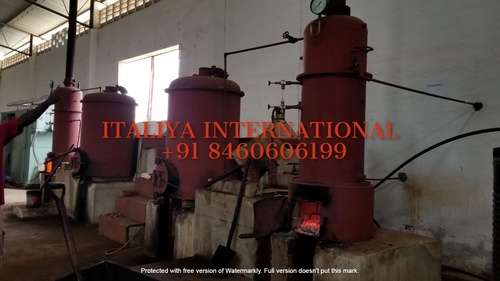

Cashew Cooker

Cashew Cooker Specification

- Power

- 5-12 HP Horsepower (HP)

- Lead Time

- 7-15 days

- Length

- 12.0 ft Foot (ft)

- Feature

- Sturdy Construction, Easy Operation

- Condition

- New

- Voltage

- 415 V Volt (v)

- Frequency

- 50 Hz Hertz (HZ)

- Usage

- For Industrial

- Function

- Steam Cooking of Raw Cashew

- Rated Frequency

- 50 Hz Hertz (HZ)

- Product Type

- Cashew Cooker

- Material

- Mild Steel

- Advantage

- Uniform Cooking, High Efficiency

- Service Period

- 12 Months

- Dimension (L*W*H)

- 12.0 ft x 6.0 ft x 7.0 ft Foot (ft)

- Height

- 7.0 ft Foot (ft)

- Capacity

- 40 kg to 320 kg per batch Kg

- Weight

- Approx. 900 kg Kilograms (kg)

- Temperature Control

- Yes

- Steam Pressure Range

- 6-10 kg/cm

- Operation Type

- Manual/Automatic

- Surface Finish

- Paint Coated

- Shape

- Rectangular

- Mobility

- Fixed

- Safety Features

- Pressure Relief Valve, Insulated Body

- Automation Grade

- Semi-Automatic

- Installation

- Onsite Support Available

Cashew Cooker Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 3 Units Per Day

- Delivery Time

- 2 Days

- Main Export Market(s)

- Western Europe, Australia, Middle East, Central America, Africa, Eastern Europe, South America, Asia, North America

- Main Domestic Market

- All India

About Cashew Cooker

Technical specification

Minimum Order Quantity | 1 Unit |

Automatic Grade | Automatic |

Brand | Italiya |

Capacity | Up to 640 Kg/hr |

Body Material | Stainless Steel |

Robust Construction for Industrial Efficiency

Engineered for heavy-duty use, the Cashew Cooker features a paint-coated, mild steel body with high-efficiency insulation. Its fixed yet spacious form factor (12 ft x 6 ft x 7 ft) accommodates large batch sizes, addressing the needs of industrial-scale cashew processing. Safety elements like pressure relief valves further enhance reliability.

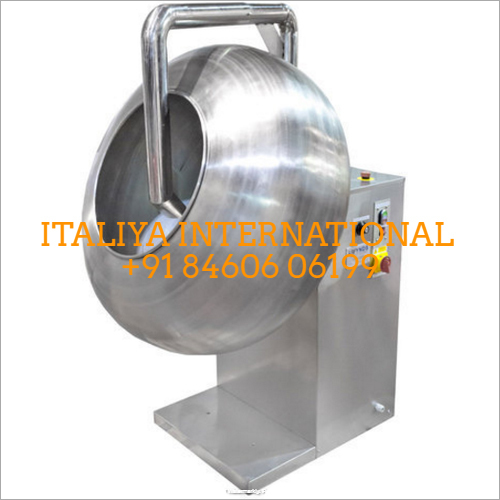

Versatile Controls and User-Friendly Operation

The semi-automatic operational grade offers the flexibility of manual or automatic processes. Integrated temperature control simplifies cooking adjustments, while easy-to-use interfaces promote straightforward workflow management. Onsite installation and training ensure your team gets up to speed quickly.

Consistent Results with Advanced Features

Uniform steam cooking is achieved through precise control of pressure, temperature, and insulated construction, enhancing product quality. The cooker's design supports optimal heat distribution and minimal energy loss, boosting batch consistency and output efficiency for operations.

FAQ's of Cashew Cooker:

Q: How does the Cashew Cooker ensure uniform steam cooking of raw cashew nuts?

A: The Cashew Cooker utilizes a controlled steam pressure (6-10 kg/cm2) and regulated temperature, combined with an insulated mild steel body. This setup promotes even heat distribution, resulting in uniform cooking across every batch and optimal product quality.Q: What safety features are integrated into the Cashew Cooker?

A: It includes a pressure relief valve and an insulated body, both designed to protect operators and maintain safe working conditions. These measures prevent pressure overload and heat-related hazards during steam cooking cycles.Q: When will onsite installation support be provided for the Cashew Cooker?

A: Onsite installation support is available upon product delivery, which typically occurs within the 7-15 day lead time after ordering. This ensures a seamless setup and training process for industrial users.Q: Where can the Cashew Cooker be used?

A: This cooker is intended for industrial facilities focused on cashew processing. Its robust build and fixed design make it suitable for factory floors, particularly in India, and for exporters, manufacturers, and service providers alike.Q: What is the process for operating the Cashew Cooker?

A: Operation involves loading raw cashews, setting steam pressure and temperature, then choosing either manual or automatic mode. The insulated cooker maintains parameters throughout the steam cycle, monitored via easy-to-use controls for consistent results.Q: What are the main benefits of using this Cashew Cooker?

A: Benefits include sturdy construction, high efficiency, uniform cooking, and easy operation. The advanced safety and control features help reduce operational risks, enhance productivity, and improve the quality of the processed cashews.Q: How much cashew can be processed per batch, and what is the power requirement?

A: Batch capacity ranges from 40 kg to 320 kg, depending on model and operation needs. The unit runs on 415 V power supply, with a rated power between 5-12 HP, suitable for industrial-scale cashew processing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Automatic Cashew Boiler Category

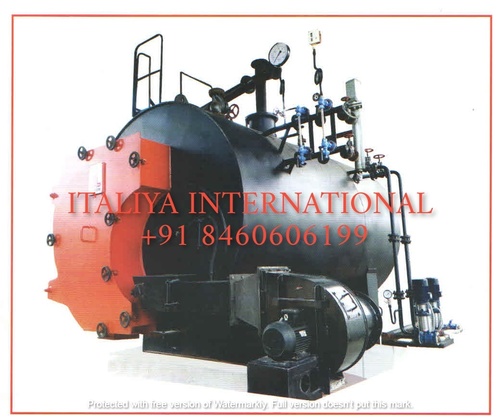

Cashew Nut Steam Boiler Machine

Price 200000.00 INR

Minimum Order Quantity : 1 Unit

Rated Frequency : 50 Hz

Material : Mild Steel

Product Type : Steam Boiler Machine

Height : 7.0 ft

IBR Boiler

Price 200000 INR

Minimum Order Quantity : 1 Unit

Rated Frequency : 50 Hz Hertz (HZ)

Material : Mild Steel

Product Type : IBR Boiler

Height : 7.0 ft Foot (ft)

RCN Cooking Cashew Steam Boiler

Price 200000 INR

Minimum Order Quantity : 1 Unit

Rated Frequency : 50 Hz Hertz (HZ)

Material : Mild Steel

Product Type : RCN Cooking Cashew Steam Boiler+

Height : 7.0 ft Foot (ft)

Cashew Nut Boiler

Price 200000.00 INR

Minimum Order Quantity : 1 Unit

Rated Frequency : 50 Hz Hertz (HZ)

Material : Mild Steel

Product Type : Cashew Nut Boiler

Height : 7.0 ft Foot (ft)

|

ITALIYA INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry